Because there is no room for error in critical aerospace manufacturing, we also rely on a powerful suite of integrated quality control software tools, Net-Inspect, which gathers data from every point in the manufacturing and inspection process. This suite of tools allows us to respond quickly to manufacturing inconsistencies, make real-time equipment adjustments, keep machines well-maintained, and review inspection data from multiple sources.

From raw materials to final inspection, our closed-loop system ensures consistent quality throughout the manufacturing process, with minimal human error or inefficiencies. Explore our capabilities below to see how precision meets automation at every step of our process.

Advanced Multi-Axis Mill-Turn Technology: Unlocking Complex Geometries

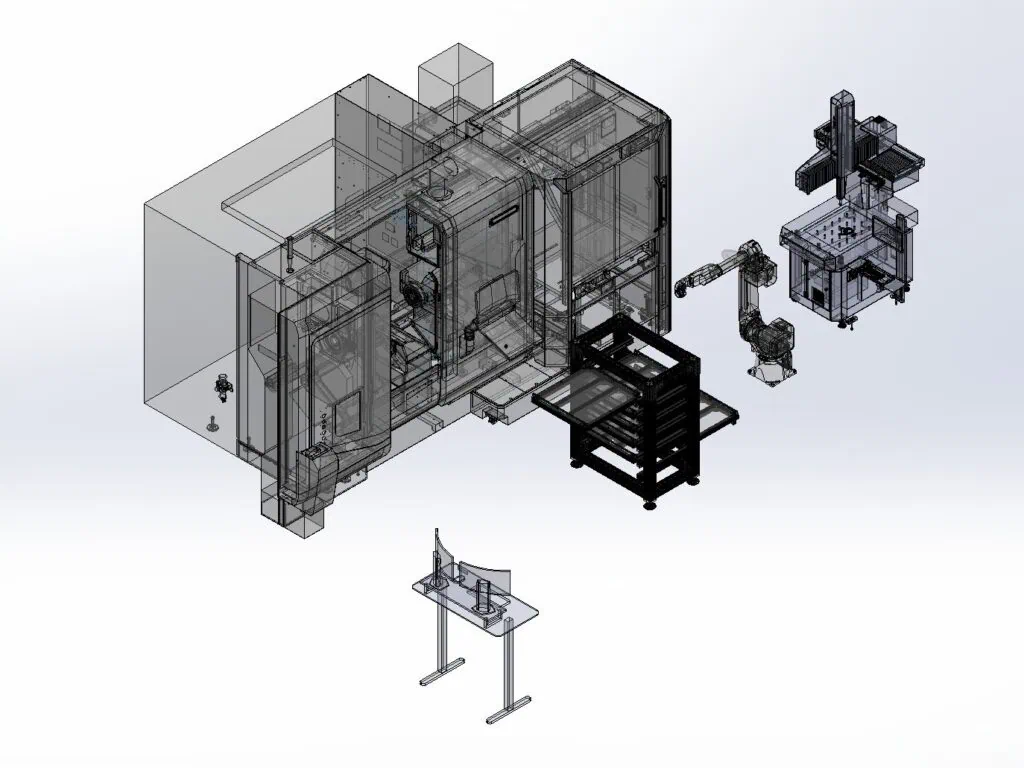

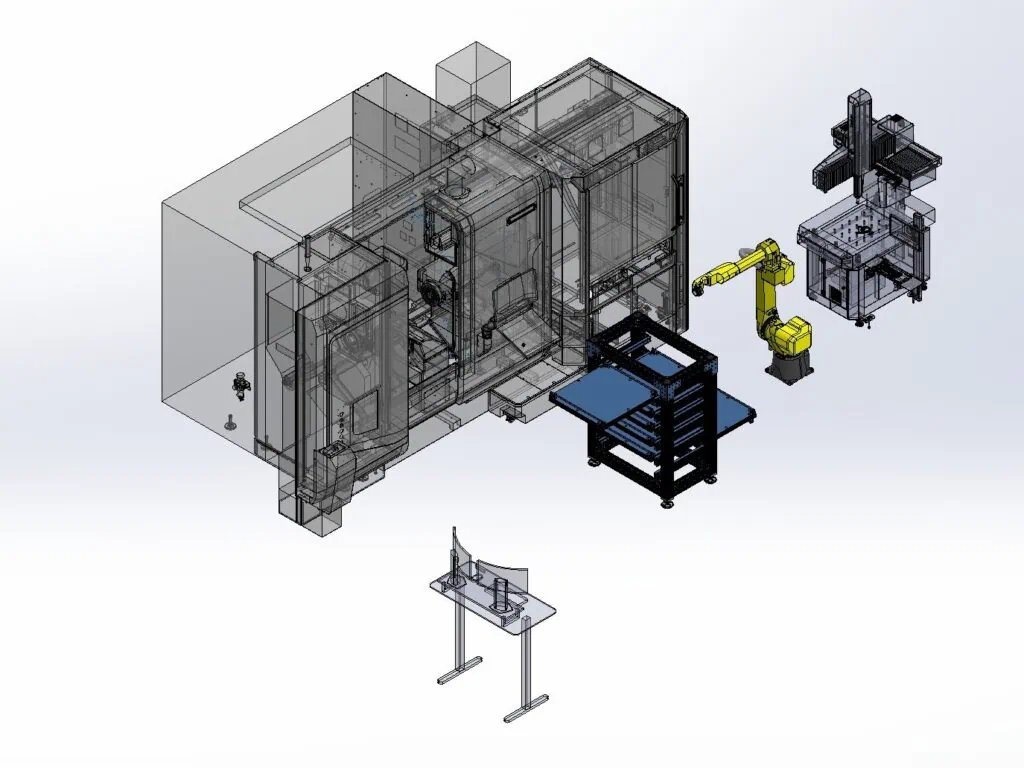

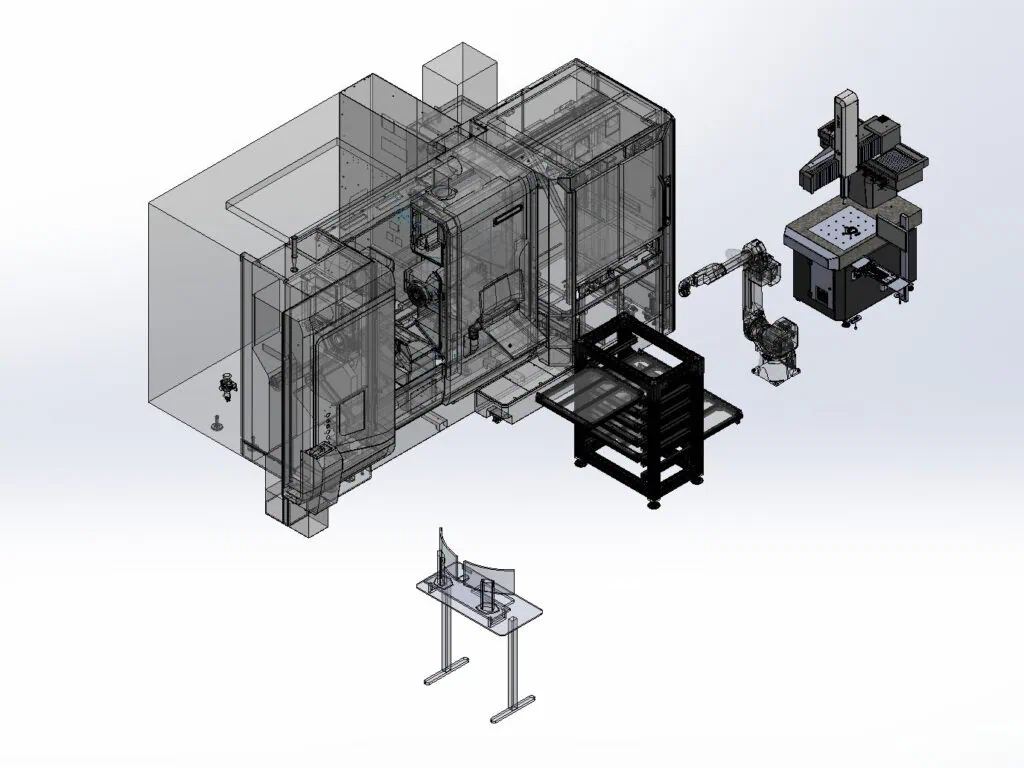

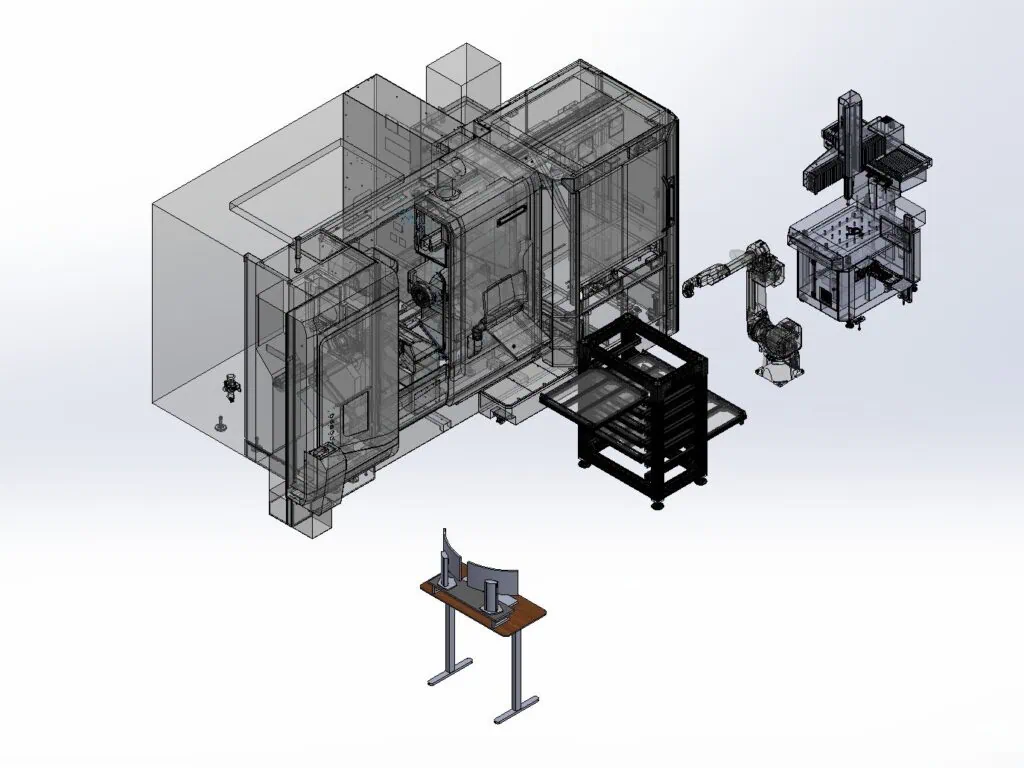

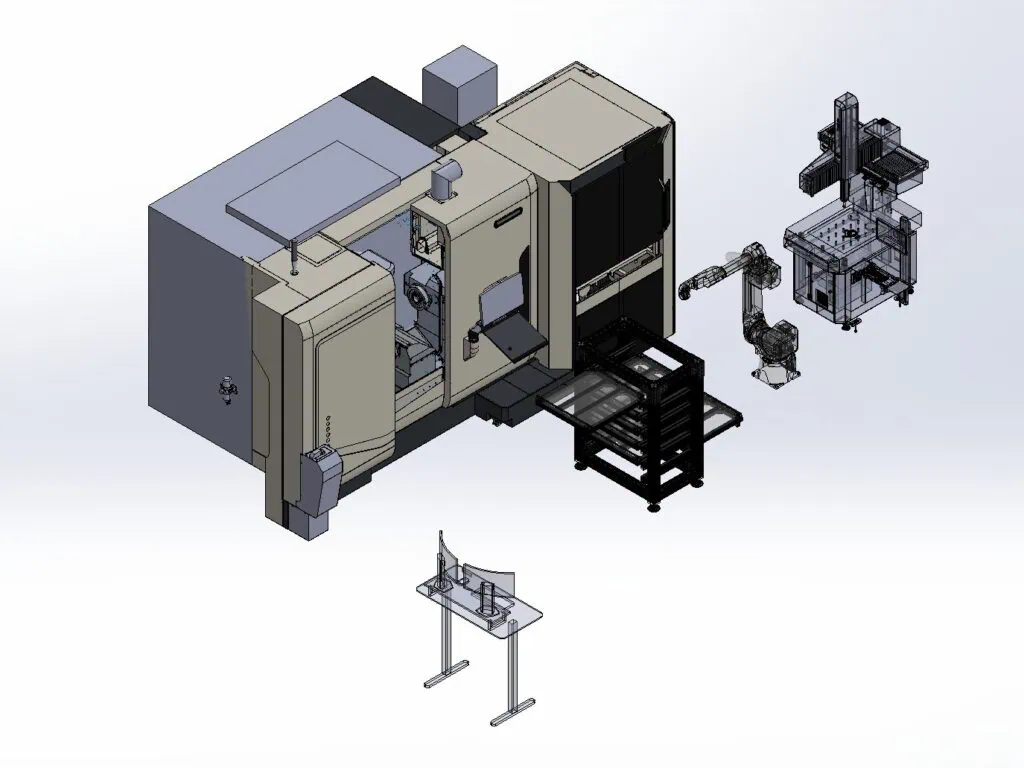

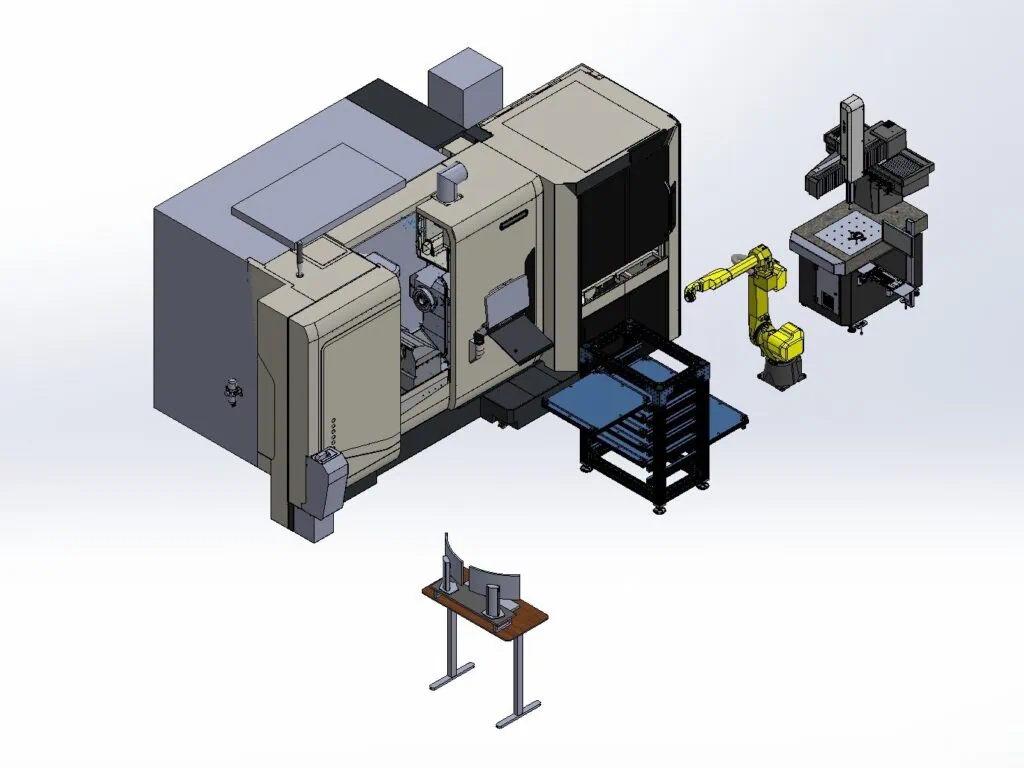

Multi-axis CNC machining is the foundation of our work. We use an advanced DMG MORI NTX 1000 automation cell to combine CNC milling and turning operations for single operation machining. This machine transforms a raw material workpiece into a finished part with one set-up and no further operations required.

With this milling and turning center we can achieve geometrically complex parts that would be difficult or impossible to produce with conventional machining methods. Not only does this streamline manufacturing, it reduces the number of times each workpiece is handled. That means shorter cycle times, high repeatability, lower risk of misalignment, and less human error.

Whether it’s intricate internal profiles, contoured surfaces, or tight-tolerance features, our equipment is designed to handle it all with simplified setups that optimize cycle times.

Stainless Steel is our specialty, and we work with a wide range of high-performance stainless steels uniquely tailored to demanding industries. Some of these alloys & superalloys include:

- 316: Marine, chemical processing, medical

- 17-4 PH: Aerospace, defense, and other high-performance applications

- Nitronic 50: Aerospace, Oil and Gas, Cryogenics, Energy

- Super Duplex: Subsea, Oil & Gas, Chemical Processing

- Invar: Aerospace, Cryogenics, Optics, and Electronics

Lights-Out Production & Robotics: The Power of Unattended Manufacturing

Autonomous Machining operates on a lights-out production model, enabled by full robotic automation. Our DMG MORI NTX1000 systems are equipped for 24/7 unattended operation, with features like:

This streamlined approach lets us produce consistent, high-quality components at scale, eliminating delays caused by shift changes or operator availability issues.

With automation driving every phase of production, we can deliver cost-effective, precision-machined parts with the reliability your industry demands. Here’s what this means for you:

Integrated Quality Assurance: Automated Inspection & Closed-Loop Control

Our quality assurance (QA) process is built around the idea that precision is only meaningful if it’s measurable. We use automated Hexagon TIGO SF CMMs to verify dimensions with an accuracy of 2.2 µm.

Inspection data is uploaded to Net-Inspect to provide real-time monitoring of measurements with SPC charts. This closed-loop system provides feed back to our CNC machines for real-time offset adjustments to maintain nominal dimensions and statistically eliminating the chance of a defective part.

These systems provide reliable, actionable data, including:

PMI & Model-Based Definition (MBD) Support: Seamless Data Integration

Autonomous Machining maintains a continuous digital thread across your entire project lifecycle. From your annotated CAD models to final part delivery, all the data is connected, retrievable, and traceable. We fully support Model-Based Definition (MBD), which enables direct working from intelligent 3D models to minimize ambiguity and errors.

This integrated digital environment drastically reduces setup time, improves consistency, and accelerates the path from concept to production. Our CAD-to-Part automation can:

- Perform feature-based programming.

- Run advanced simulations.

- Automate programming CMM routines.

- Generate optimized G-code for CNC machines with minimal manual edits.

Cloud-Based Integration & Traceability

We support every job with ITAR-compliant, cloud-based ERP and quality management systems. Using platforms like StartProto and Net-Inspect, we deliver full transparency and compliance from the first quote to the final shipment.

Inspection records, material certificates, FAIRS, and more are shared digitally through Net-Inspects eSource platform. Scanning a single QR code allows our customers to access this documentation from the cloud. These systems allow us to:

- Track every lot of raw material used.

- Identify non-conformance events and their root causes.

- Maintain workflow progress from step to step.

- Monitor the effects of any corrective or preventive actions taken.

- Maintain version control on work instructions and part programs.

- Generate and share real-time status updates with customers.

- Plan product quality control processes and PPAP requirements.

- Manage packing and shipping documentation.

API-Driven Efficiency & Smart Manufacturing

There’s no need to change your existing systems when you partner with Autonomous Machining. We use API connectivity to integrate our infrastructure with your systems seamlessly. API is the technological backbone that automates data exchange.

Here’s what that means for you:

Beyond data transfer, our API framework supports smart manufacturing insights that come from real-time analytics. These adaptive capabilities allow us to remain responsive, agile, and aligned with your supply chain. The result is a highly adaptive and efficient manufacturing ecosystem that is well-positioned to respond quickly to changing demands.

By leveraging AI-powered tools, we can:

Agile & Rapid Response Manufacturing: Speed to Market with Precision

Today’s competitive environment calls for not only precision but speed. At Autonomous Machining we’ve optimized our process for rapid response manufacturing, which gives you the freedom to iterate faster, scale more efficiently, and launch sooner.

Thanks to our automation and digital integration, we can:

Whether you’re pushing to meet a critical deadline or prototyping your product for performance improvements, our system is built to keep things moving with parts that are precise, on time, and ready for the next phase.

Our Capabilities

Precision CNC Manufacturing Capabilities from Autonomous Machining

At Autonomous Machining, precision engineering meets intelligent automation. From advanced mill-turn machining to real-time inspection and seamless digital integration, our capabilities are thoughtfully designed to support mission-critical applications with speed, accuracy, and transparency.

We don’t just make parts. We make the entire manufacturing process smarter, faster, and more reliable. Whether you’re in aerospace, defense, medical, or other high-performance industrial applications, our systemized approach to precision CNC machining delivers consistent results at scale.

Let’s build something exceptional. Request a quote today to get started.